Gas Fitter Class A

Gas Fitter Class A (Red Seal) is now the top-level gas trade certification in British Columbia for large commercial and industrial gas-fired systems over 120 kW, and AceTech is fully certified to deliver these services safely and legally. That makes AceTech one of the few local partners able to handle high‑capacity boilers, burners, process heaters, and make‑up air systems at full scale for businesses across Metro Vancouver. (source)

What Gas Fitter Class A Means In BC

- The Gasfitter – Class A Red Seal trade covers appliances and equipment, including those exceeding 400,000 BTU/hr (120 kW), which is the threshold between standard and large‑capacity gas systems.

- BC’s Gas Safety Regulation ties this threshold to who can legally work on the equipment: Class B qualifications are limited to 120 kW, while Class A is required for larger, high‑input appliances and forced‑draft equipment above 409,600 BTU/hr.

In practice, that means a Gas Fitter Class A is the only certification designed for the kinds of commercial and industrial gas projects where input ratings, burner complexity, and safety interlocks are far beyond typical residential work. (source)

Why Class A Matters For Commercial & Industrial Clients

- Large commercial and industrial gas appliances can consume thousands of cubic metres of fuel per hour and rely on sophisticated burner management systems, safety interlocks, and integrated control interfaces.

- Technical Safety BC requires appropriate certification not only for installation and alteration, but also for commissioning and approval of high‑input direct‑fired equipment, make‑up air units, and forced‑draft appliances over 120 kW.

For building owners, property managers, and plant operators, partnering with a properly certified Class A Gas Fitter helps reduce safety risk, protect liability, and ensure compliance with provincial regulations and inspection standards. (source)

High‑Capacity Gas Equipment AceTech Can Service

AceTech’s Gas Fitter Class A capability is built around high‑input, high‑duty systems that keep commercial and industrial operations running.

- Gas‑fired equipment over 120 kW / 409,000 BTU/hr – including large space‑heating appliances, high‑capacity water and hydronic heaters, and process‑load equipment that exceed Class B limits.

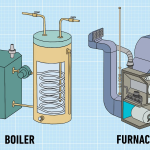

- Commercial & industrial boilers (condensing and non‑condensing) – from traditional firetube and watertube boilers to high‑efficiency condensing systems, including commissioning, combustion tuning, and retrofit work.

- Modulating boiler systems – fully modulating burners and control strategies that match boiler output to real‑time load, improving efficiency and comfort while reducing cycling and wear.

- Make‑Up Air Units (MAU) – especially direct‑fired non‑recirculating make‑up heaters and other MAUs that fall under Technical Safety BC’s commissioning and approval requirements.

- Direct‑fired and indirect‑fired equipment – including direct‑fired non‑recirculating make‑up heat, industrial air handlers, and indirect‑fired packaged units requiring proper combustion design and venting.

These systems demand a mix of combustion expertise, controls knowledge, and code familiarity that aligns exactly with what Gas Fitter Class A training and Red Seal standards are designed to provide. (source)

Advanced Burners & Combustion Systems

Modern commercial and industrial combustion equipment is all about efficiency, reliability, and emissions performance—and AceTech’s Gas A services are built around that reality.

- Premix burners use premixed fuel and air to produce uniform flame distribution, high turndown ratios, and low carbon monoxide emissions—ideal for condensing boilers and process heaters.

- Power / forced‑draft burners rely on combustion air fans and carefully engineered airfoil designs to deliver stable airflow, improved efficiency, and quieter operation, especially on high‑input boilers and process heaters.

- Low‑NOx and fully modulating burners are engineered to minimize nitrogen oxide formation using techniques like staged combustion and parallel‑positioning controls, helping facilities meet tightening air‑emissions requirements.

- Pilot systems and direct spark ignition (DSI) require precise setup, verification of safety interlocks, and proper flame‑safeguard operation to ensure safe light‑off and reliable sequencing of large burners.

Manufacturers of low‑NOx, premix, and process burners emphasize proper commissioning, control setup, and ongoing maintenance to achieve published performance—exactly the scope where a qualified Gas Fitter Class A is essential. (source)

Industrial Gas Appliances & Process Heating

In industrial and process environments, gas‑fired systems often go far beyond basic space heating.

- Process heaters and thermal fluid systems use high‑capacity burners (often in the multi‑MMBTU/hr range) to heat fluids, oils, or air streams for manufacturing and industrial processes.

- High‑capacity unit heaters and infrared heating systems are commonly used in warehouses, distribution centres, production floors, and vehicle bays, where mounting height, coverage, and combustion safety all need careful design.

- Custom gas‑fired equipment and unit heaters often combine engineered burners, custom controls, and specialized safety interlocks, making proper certification and commissioning critical to safe, reliable operation.

Because these systems often operate at high input ratings and serve mission‑critical processes, they fall squarely into the Class A Gasfitter scope for installation, modification, and troubleshooting. (source)

Compliance, Commissioning, And Safety

Working with a certified Gas Fitter Class A team like AceTech helps align every project with BC’s gas safety framework.

- BC’s Gas Safety Regulation and Technical Safety BC guidance clearly distinguish what qualifications are required for direct‑fired make‑up heaters, conversion burners, and forced‑draft appliances over 120 kW—areas where Class A is explicitly referenced. You can review the Gas Safety Regulation at: https://www.bclaws.gov.bc.ca/civix/document/id/complete/statreg/15_103_2004

- Red Seal information on the Gasfitter – Class A trade, including typical equipment and sectors served, is available at: https://red-seal.ca/eng/trades/gasfitter-a.shtml

- For context on the 120 kW threshold and other gas certifications in BC (Class B, gas venting, etc.), see Technical Safety BC’s gas certification pages: https://www.technicalsafetybc.ca/technologies/gas/gas-certification

AceTech’s role is to navigate these requirements on behalf of owners and facility managers—ensuring permits, inspections, commissioning approvals, and documentation all align with current regulatory expectations. (source)

Why Act Now On Gas A Services

Because Gas Fitter Class A as a Red Seal trade is relatively new in Canada and BC’s regulations tie high‑capacity work to appropriate qualification, there is still limited competition in this space—especially for commercial and industrial projects. Early adopters who standardize on properly certified Class A partners are better positioned for:

- Future emissions and efficiency requirements on boilers, burners, and process equipment.

- Stricter enforcement around commissioning of direct‑fired make‑up air units, forced‑draft appliances, and other high‑input gas systems.

For building portfolios, industrial plants, and commercial facilities across Metro Vancouver and the surrounding BC communities, formalizing a relationship with a Gas Fitter Class A contractor like AceTech is a strategic way to de‑risk current assets and upcoming projects. (source)

AceTech Gas Fitter Class A – How To Get In Touch

AceTech is a family‑operated plumbing, heating, cooling, and refrigeration company serving Metro Vancouver and nearby communities including Surrey, Burnaby, Coquitlam, Richmond, Langley, Delta, Maple Ridge, Pitt Meadows, Port Coquitlam, West Vancouver, and North Vancouver. With full Gas Fitter Class A certification, AceTech can support everything from high‑capacity boilers and MAUs to custom industrial gas appliances and low‑NOx burner upgrades. (source)

For Gas Fitter Class A projects, consultations, or emergency service:

- Company: Ace Tech Plumbing, Heating, Cooling & Refrigeration (Ace Tech Plumbing & Heating LTD)

- Phone (24/7 Emergency Service): 1‑844‑704‑4177

- Website: https://acetechltd.ca/

- Contact Page / Online Request: https://acetechltd.ca/contact/

Businesses planning new boiler plants, combustion upgrades, make‑up air improvements, or industrial gas process changes can reach out to AceTech today to discuss Gas Fitter Class A solutions tailored to their site and equipment.